We Go Beyond Clean

At Carlton & Chastain Orthodontics, we take the safety of our staff and patients very seriously. In our office, we believe you can never be ‘too safe or too clean’! That’s why we’ve partnered with the professionals at MediClean & Shield (MCS) for the ultimate infection prevention and surface disinfecting practices found in any modern-day dental/orthodontic office. The MCS team uses a patented and EPA approved surface disinfecting and treatment application, along with a set of proprietary surface testing and water testing protocols that measure microbial contamination levels for proven, lasting results! Look for the MCS certification sticker outside our office door the next time you come in for an appointment.

MCS offers technology enhanced infection control for all types of health care facilities.

Infection Control Guidelines For Dental/Orthodontic Offices

To better understand infection prevention, let’s start by reviewing the Centers for Disease Control’s list of “Standard Precautions”, which are the minimum infection prevention practices that apply to all types of patient care. Standard Precautions in dental and orthodontic offices include:

- Hand hygiene

- Use of personal protective equipment (PPE) like masks, gloves, and eye protection

- Clean and disinfected surfaces

- Sterile instruments and devices

- Respiratory hygiene/cough etiquette

- Sharps safety (engineering and work practice controls)

- Safe injection practices

Dental Unit Waterline (DUWL) Maintenance And Testing

Why Is It Important To Main Specific Levels Of Water Quality?

The presence of substantial numbers of pathogens in dental unit waterlines has generated a growing concern about procedural water quality. In 1993 the CDC recommended that DUWLs be flushed every morning to reduce the microbial build-up. However, follow-up studies indicated this practice did not affect the biofilm in the waterlines or reliably improve the water quality. In 1995 the ADA began asking DUWL manufacturers to provide equipment with the ability to deliver treatment water with <200 CFU/ml of unfiltered output from waterlines.

The majority of organisms recovered from dental waterlines are common heterotrophic water bacteria, but in large numbers these can have a negative impact on patients.

Read More About CDC Guidelines For Infection Control In DUWLs >

Disinfecting Protocols For DUWLs

In Most Cases, Following These Protocols Will Ensure Compliance With Waterline Recommendations

- Use an approved waterline disinfectant solution. At minimum, this should be run through the dental unit once a week, or use a full-time disinfectant option.

- Purge the dental unit with air at the end of each week and let dry. To do this, remove and empty the water bottle then reinstall it. Remove the handpicks. Hold the handpick tubing and air/water syringe over a sink or bucket and run until all water is purged from the system. Turn the unit off and allow to dry over the weekend.

- It is also advisable to use an approved biofilm remover to “shock” the system at least quarterly.

- Regular water analysis reports can aide in risk management! Test dental water units quarterly to make sure bacterial levels remain less than 500 CFU/ml of water.

Effective Disinfectants Against Viruses

After living through a pandemic, we all know that disinfecting and routinely cleaning commonly touched surfaces helps to kill viruses, but do all disinfectant’s work the same on all viruses?

Let’s start with the basics on viruses… they’re a microscopic parasite, meaning they do not contain components of normal living organisms like plants, animals or bacteria because they cannot reproduce without a host. To reproduce they attach and use their genetic material to trick the host cell into making more copies of the virus. The catch is, they must enter the proper host’s cells. For example, because SARS-CoV-2 is a respiratory virus, it primarily reproduces within cells that line the respiratory tract.

Regardless of their host, viruses can be divided into different categories based on their genome structure, shape (morphology), size, and presence or absence of a lipid membrane called an envelope. Depending upon the virus type and environmental conditions, viruses can survive for extended periods on surfaces; remaining infectious even after several days.

The COVID-19 Coronavirus (named after its ‘crown’ shape when viewed under an electron microscope) is an “enveloped RNA virus”. All coronaviruses have a similar structure and can stick to surfaces, but are also able to be killed with disinfectants. Therefore, cleaning, sanitizing and disinfecting surfaces is a key component in the ongoing fight to eliminate these microbial threats!

PermaSafe™ is an EPA Approved Hospital-Grade Disinfectant

The PermaSafe™ system is a patented and EPA-registered disinfection & long-term microbial control system and surface protectant for virtually every common surface or substrate within any environment.

The PermaSafe™ system is a patented and EPA-registered disinfection & long-term microbial control system and surface protectant for virtually every common surface or substrate within any environment.

PermaSafe’s products have been approved by the EPA for use against SARS-COV-2, the coronavirus that causes COVID-19. (Please note, only the EPA regulates claims on disinfectant product labels. Before a company can sell or market a disinfectant whose label claims to kill a certain pathogen, the EPA must authorize that claim during the registration process. All claims must be supported by sound science and testing data.) PermaSafe CLEAN meets the EPA’s emerging pathogen requirements for viruses showing efficacy against a wide range of enveloped and non-enveloped viruses, both large and small.

When following product label directions, the EPA specifies that disinfectant products on List N are approved to kill SARS-CoV-2, the coronavirus that causes COVID-19, because they:

- Demonstrate efficacy against the coronavirus SARS-CoV-2 (COVID-19);M

- Demonstrate efficacy against a pathogen that is harder to kill than SARS-CoV-2 (COVID-19); or

- Demonstrate efficacy against a different human coronavirus similar to SARS-CoV-2 (COVID-19).

How Do You Know If A Surface Is REALLY Clean?

You Test It!

The Sciene Behind PermaSAFE

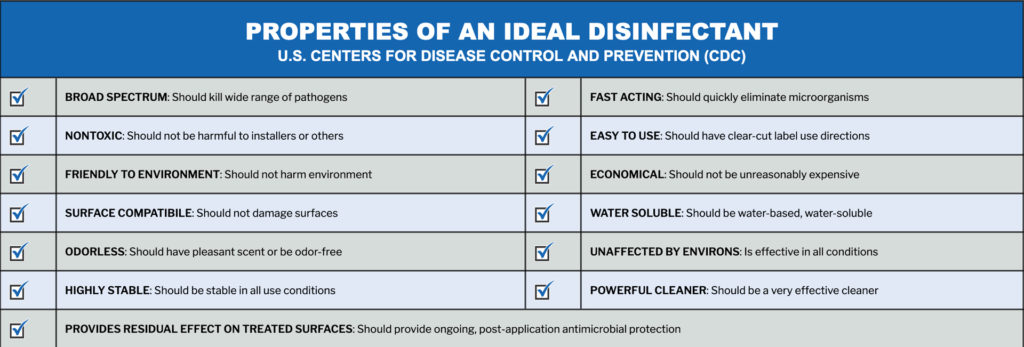

Effective antimicrobials are not new to the market, however the PermaSafe system provides continuous antimicrobial control for up to 3 months without the repeated use of harmful, toxic chemicals that conventional disinfectants and antimicrobials use.

We also love PermaSafe because it’s odor free, skin contact safe, non-toxic, non-flammable, non-corrosive, non-hazardous; safe to use on electronics; environmentally neutral and eco-friendly!

Here's How The Process Works

Step 1

Initial Consultation

Step 2

Pre-Test & Measurement

Step 3

Cleaning & Protection

Step 4

Post-Test & Measurement

Step 5

Clean Certification

Step 6

Maintenance & Management

PermaSafe CLEAN is the patented multi-purpose, multi-surface, broad-spectrum, germicidal cleaner, food contact surface sanitizer, and hospital disinfectant that deep cleans and decontaminates surfaces to ensure the subsequent application of PermaSafe SHIELD achieves an effective, durable protective bond. It’s also EPA and NSF Registered, FDA Approved and CDC Compliant.

PermaSafe SHIELD is the patented antimicrobial agent that molecularly bonds to the surface to which it is applied, effectively becoming a permanent part of that surface. As the coating dries, millions of microscopic antimicrobial “spike-like” appliances form and extend from the surface. These “spikes” are actually long ISO polymer chains of positively charged atoms that represent a deadly dual threat to microbes.

Once cured, the antimicrobial coating forms an invisible protective shield that inhibits the growth of microorganisms and helps prevent the growth and spread of bacteria. Because the cell walls of harmful microorganisms are negatively charged, they are electrostatically drawn towards and pulled onto the positively charged spikes and destroyed, as the spikes both impale and electrostatically “shock” the microbes.

The electrostatic sprayer method kills up to 99.999% of pathogens. It also kills the COVID-19 virus.

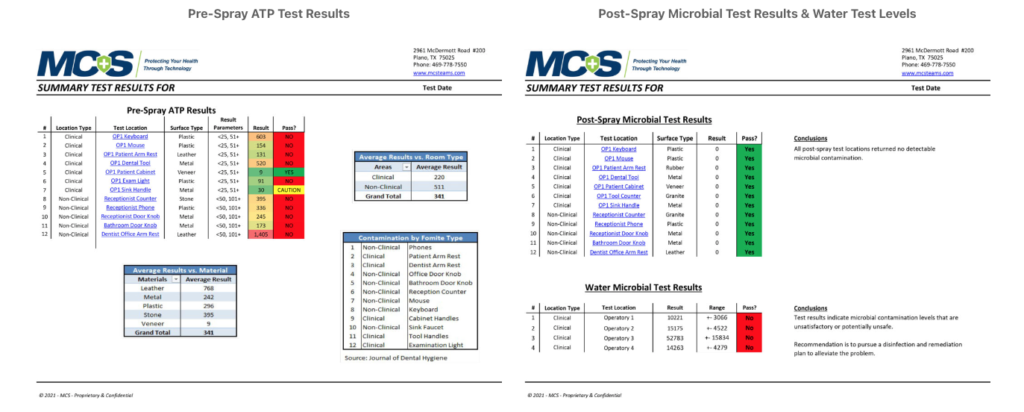

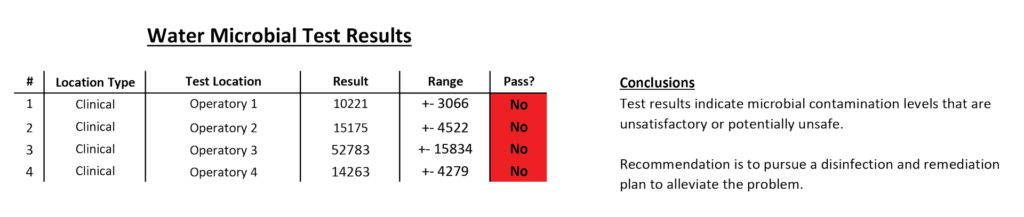

Proven Test Results

ATP (Adenosine Triphosphate) is an energy molecule found in all plant, animal and microbial cells… basically the food for microorganisms to grow.

Microbial activity refers to microorganisms such as viruses, bacteria, and fungi that can infect humans and pets. Since these microorganisms need a food source to live and grow, they feed off of ATP. Spot testing surfaces ensures that our office remains free of these harmful microorganisms, and that our office environment won’t be a breeding ground for future microbial growth.

Have Questions?

Learn About MCS Infection Control Services >

Read more about the science behind electrostatic spraying and microbial testing >

Sample Summary Test Results

Read More About Electrostating Spraying And Microbial Testing >